activated carbon adsorption tower

Working principle of Activated carbon adsorption tower The system is in the role of the fan, the airflow makes upward movement from the imports in the bottom of the tower, besides , the chemical liquid makes downward movement . In the same time, ther

Working principle of Activated carbon adsorption tower

The system is in the role of the fan, the airflow makes upward movement from the imports in the bottom of the tower, besides , the chemical liquid makes downward movement . In the same time, there are numbers of filler in the tower , increase the contact area between liquid and gas , so achieve the purification effect .The clean gas is discharged through the upper layer of the demister .Due to the different composition of the gas , acid liquid or alkali were selected as the chemical liquid .

Features of Activated carbon adsorption tower

1.The purification tower could made of PVC,PP,FRP,carbon steel or stainless steel.

2. Process large air volume , and the performance is stable .

3. The operation and the maintenance are both convenience .

4. The purification efficiency is up to 99.9%.

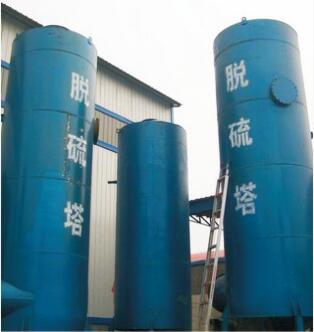

Structure and composition of Activated carbon adsorption tower

Waste gas purification tower is generally made up of draught fan, packing layer, demister, circular watering pipe, circulating water channel, etc.

practical significance of Activated carbon adsorption tower

Currently, waste gas purification tower has been successfully used to deal with spraying waste gas, printing waste gas, chemical waste gas, electronic waste gas, medical waste gas, asphalt waste gas, mechanical exhaust, sewage waste gas, etc. And it also has a great success in meeting the national discharge standard. At the same time, it removes odour and improves the environment. It is especially suitable for the waste gas which is of low dust capacity, low concentration and great peculiar smell.

This machine aims at separating gas from the contaminant and translating into innocuous substance and then cleaning gas. The waste gas intakes to the purifying column through the air hose, after packing, the waste gas and absorption liquid are completely contacted and have a neutral reaction. After purified, the waste gas discharges into the environment after demisting and dehydration. Its motivation is draught fan.

|

Surface area(m2/g)

|

Specific surface area(m2/g)

|

Average pore size o (A)

|

Pore volume(mL/g)

|

Bulk density(g/cm3)

|

Thickness(mm)

|

benzene

Adsorption capacity(%)

|

iodine

Adsorption capacity(mg/g)

|

|

1.5-2.0

|

1100-1500

|

17-26

|

0.25-0.7

|

100-160

|

250

|

>38

|

900-1300

|